Shanghai Meishan Iron and Steel Company: 60000J pendulum type DWTT impact testing machine

Equipment name: 60000J pendulum DWTT impact testing machine

Device model: PIT604E

Application: Measuring the impact resistance of metal materials under dynamic load。

Manufacturer: Shenzhen Wanji Test Equipment Co., LTD

Equipment use: 60000J pendulum DWTT impact testing machine system is used to measure the impact resistance of metal materials under dynamic load, in order to judge the mechanical properties of materials under dynamic load, for the research and development of high specification, large thickness pipeline steel。The device can accurately measure the impact energy absorbed by the specimen during impact fracture。This equipment is developed by Wanyi Company, including a number of patents。

Test criteria met:

GB/T 8363-2007 "Ferrite steel drop hammer tear test method"

ASTM E436-03 Standard Test Method for Drop-Weight Tear Tests of Ferritic Steels

API RP*5L3-96 Conducting Drop-Weight Tear Tests on Line Pipe

GB/T 3808-2002 "Pendulum impact testing Machine test"

JJG 145-2007 "Pendulum Impact Testing Machine"

Main technical parameters and requirements:

(1) Nominal energy AN: 60kJ ~ 20kJ, can be set to 20kJ, 30kJ, 40kJ, 50kJ, 60kJ impact energy, can also be set to any value between 20kJ ~ 60kJ;It can be set on the touch screen of the computer or control cabinet。

(2) Pendulum pre-lifting Angle: 135 ~ 63

(3) Pendulum torque M(impact constant): 32153.9N.m

(4) The distance from the pendulum axis to the center of the sample (pendulum length)l: 2400mm

(5) Impact speed: 8.96~5.07m/s (V=)

(6) Span of anvil: mm

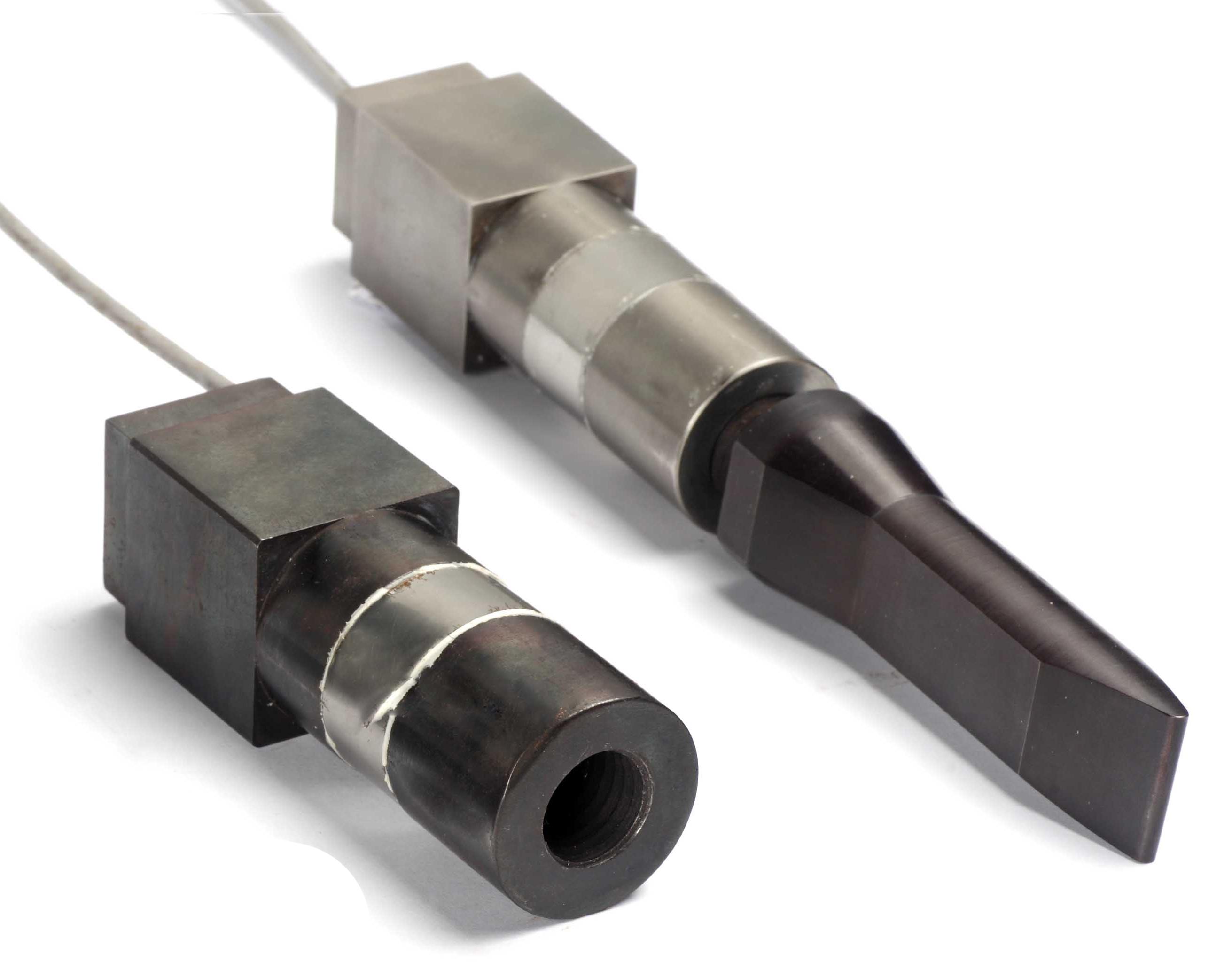

(7) Anvil back-up roll: prismatic 100±0.04mm, Angle 11°±0.5°,半径14.3±0.4mm

(8) Anvil inclination: 11±1

(9) Impact blade radius: 25.4±0.2mm

(10) Impact blade thickness: 50.8±0.4mm

(11) Hardness of impact blade and anvil back-up roll: 58HRC ~ 62HRC (effective impact times are not less than 10,000 times)

(12) The foundation construction drawing provided by the equipment supplier (the detailed size of the foundation, the foundation anchor bolts and other requirements of the foundation, etc.), the mass of the foundation is not less than 40 times the mass of the pendulum

(13) The parallelism between the pendulum axis and the measurement datum of the testing machine should be within 2/1000

(14) When installing the testing machine, the levelness of the datum should be within 2/1000

(15) The pendulum should be sufficiently rigid。When the pendulum is suspended freely, the gap between the impact blade and the specimen side is 0.Within 8mm

(16) The Angle of the swing plane of the pendulum relative to the axis of the pendulum is 90±0.08

(17) The impact blade is in full contact with the entire width of the specimen

(18) The center line of the impact blade should pass the midpoint of the span of the support, and the deviation should not exceed 0.4mm

(19) The mass of the frame base is not less than 15 times the mass of the pendulum, the material is rolled steel plate (45#), and the material of the sample support is forged steel

(20) The maximum allowable relative error between potential energy AP and nominal energy AN is ±0.4%

(21) The energy loss caused by bearing friction and air resistance of the testing machine should not exceed 0 of the nominal energy AN.4%

(22) The Angle of the horizontal axis of the contact line sample of the impact blade should be 90±0.5